DC To AC Solid State Relay

PRODUCT SPECIFICATION

DC to AC Up to 300 AMP PANEL MOUNTED SSR

Salient Features:

- Op to Isolation 2500 Vrms.

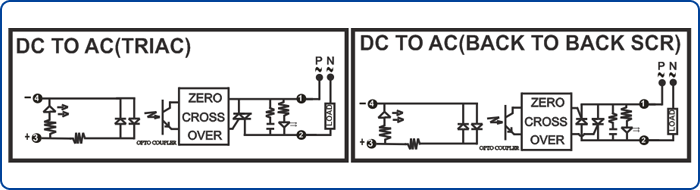

- True Zero Cross Over.

- Virtually free from EMI/RFI.

- Input LED indication/Output reversed LED Indication.

- Input TTL Compatibility Optionally CMOS Compatibility.

- Output to body 4Kv islotation.

- Noiseless without chattering and Fast Switching.

- Arceless Switching, No Contact Bounce.

- Heat Sink ± Din Rail Mounting ( 35mm ).

- Reverse polarity protection.

- Output N/O configuration, N/C (optionally).

- Inbuilt snubber/ PIV: 800Vpk, 1200Vpk, 1600Vpk (optionally).

- With Poly carbonate shroud.

- Random type of S.S.R (optionally).

Advantages:

- Contac less Logic Relay with Switching Function Performed by Semiconductor Device.

- True Zero Voltage turn ON/OFF.

- Input Output Isolation 2500VA.

- Virtually Free Electromagnetic Interference and Radio Frequency Interference.

- No Moving Contacts So No Acoustic Noise.

- Dustproof, Immunity to Humidity, No effect of Alkaline / Acidic Atmosphere.

- High Speed And High Frequency Switching.

- Shock And Vibration Resistance.

- Longer Life Due to Infinite Number of Switching.

Precaution:

- For Load Current More Than 3Amp External Heat sink is Must.

- Apply Heat sink Pest On the Base Plate of the SSR Before Mounting it on External Heat sink.

- Fast Acting Fuse Require For Protection Of SSR.

- SSR Rating Should Be More or Equal to Maximum Jerk Current of Load.

- For Additional Transient Over Voltage Protection Add MOV.

- Do Not Check SSR by Meter OR Continuity Tester. Otherwise, It will Always Shows OPEN.

Application:

- Temperature Control System.

- Microprocessor Based Control.

- Traffic Signal Controls.

- Laboratory Equipments.

- Primary Transformer Control.

- Switching of Contactors.

- Three Phase Motor Control..

- Photography Process Equipments.

- Process Control Systems.

- Medical Equipments.

- Business Machines.

- ON / OFF of Solenoid Valve.

- CNC Machine Control.

- Switching of Contactors.

- Automatic Vending Machine.

- Plastic And Packaging Machine.

INPUT SPECIFICATION & OUTPUT SPECIFICATION TECHNICAL DATA

| INPUT SPECIFICATION | OUTPUT SPECIFICATION | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| INPUT ON VDC | INPUT OFF VDC |

INPUT CURR mA | VDRM VPK |

IT A |

VTM VAC |

ITSM A |

IDRM mA |

IHO mA |

DV/DT |

I2t A2S |

| 3-32 | 1.0 | 6-12 | 200-800 | 10 | 1.6 | 100 | 10 | 75 | 200 | 50 |

| 16 | 1.6 | 160 | 10 | 75 | 200 | 120 | ||||

| 1.0 | 25 | 1.85 | 260 | 10 | 150 | 250 | 300 | |||

| 40 | 1.85 | 300 | 10 | 150 | 250 | 400 | ||||

| 3.32 | 6-12 | 400-800 | 25 | 1.6 | 400 | 12 | 120 | 500 | 1250 | |

| 40 | 1.6 | 500 | 120 | 500 | 1250 | |||||

| 50 | 1.9 | 250 | 1000 | 1250 | ||||||

| TYPE OF S S R |

OUTPUT SPECIFICATION | LOAD CURRENT @ 55° C. WITH HEAT SINK |

INPUT ON VDC | INPUT OFF VDC | INPUT CURRENT mA | ||

|---|---|---|---|---|---|---|---|

| EMT 48 10 DC | 480VAC

PIV

800VPK

1200VPK 620VAC PIV 1600VPK |

10 | 50 | 6 AMP | 3 - 32 VDC | 1.0 | 1 - 20 |

| EMT 48 16 DC | 16 | 120 | 10AMP | ||||

| EMT 48 25 DC | 25 | 300 | 16 AMP | ||||

| EMT 48 40 DC | 40 | 450 | 24 AMP | ||||

| EMT 48 50 DC | 50 | 3000 | 32 AMP | ||||

| EMT 48 75 DC | 75 | 5100 | 45 AMP | ||||

| EMT 48 100 DC | 100 | 7200 | 52 AMP | ||||

| EMT 48 125 DC | 125 | 8200 | 66 AMP | ||||

| EMT 48 150 DC | 150 | 18000 | 82 AMP | ||||

| EMT 48 200 DC | 200 | 25000 | 106 AMP | ||||

| EMT 48 250 DC | 250 | 32000 | 132 AMP | ||||

| EMT 48 300 DC | 300 | 45000 | 106 AMP | ||||

HIGH PIV SOLID STATE RELAY WITH DCB TECHNOLOGY

| 3 - 32 | 1.0 | 8 - 32 | 1200 - 1600 | 50 | 2.0 | 520 | 10 | 250 | 1000 | 1250 |

| 75 | 2.0 | 1150 | 10 | 250 | 5000 | |||||

| 90 | 2.0 | 1350 | 10 | 250 | 5000 | |||||

| 125 | 2.0 | 1350 | 10 | 300 | 5000 | |||||

| 150 | 2.0 | 1350 | 15 | 300 | 8000 | |||||

| 175 | 2.0 | 1500 | 15 | 300 | 15000 | |||||

| 205 | 2.0 | 2250 | 20 | 350 | 25000 | |||||

| 250 | 2.0 | 2500 | 20 | 350 | 32000 | |||||

| 305 | 2.0 | 2750 | 20 | 350 | 45000 |